Publications Portfolio

Vacuum Unit Revamp

Vacuum distillation operations are quite effective and can upgrade the bottoms of the crude unit into higher-valued products and blending streams. Nevertheless, refiners are exploring all opportunities to maximize capacity while minimizing equipment modifications. Revamping vacuum towers is key for upgrading the total refinery throughput. Retrofitting the vacuum tower poses many challenges; however, the benefits from such projects outweigh the negatives. The following examples demonstrate opportunities to increase performance of an existing vacuum tower.

Interacting with Vendors for Distillation Tower Internals

Distillation towers are generally considered the lead separation technology in refinery and chemical operations. Sophistication of tower internals, which are the heart of distillation towers, has increased exponentially ¾ starting from bubble cap, sieve and valve trays, through 1st generation random packing to structure and mesh packing. All give a variety of operating ranges suitable for the grass-root design and revamp of distillation towers.

Modeling Water Treatment Plant

Modeling wastewater treatment parameters such as concentrations of components and particle size distribution of solid particles, viable biomass and dead biomass requires the simulation of several processes within various wastewater plant layouts. Although the software is not a specialized tool for the simulation of the UV disinfection unit, it predicts parameters critical for such purpose. Multi-purpose flexible software was thus developed with the ability to simulate several key processes used in the municipal and industrial wastewater treatment processes. A special feature is the ability of the software to predict particle size distribution at the clarifier–thickener unit outputs. A presented case study showed a simulation of the typical biological and settler processes usually located upstream of the UV disinfection unit.

Recover Lubricant Gasoil

Since its introduction, vacuum distillation (VD) has become a key refinery operation and is used to continue upstream atmospheric distillation. Topped crude is processed at sub-atmospheric conditions to recover valuable gasoils at low temperatures and to avoid coking and overcracking. Typically, VD towers recover gasoils for downstream cracking units, while other towers produce lubricants. Also, VD is used to produce lube-grade gasoils for further processing by lubricant production facilities.

Polydisperse Suspension in Waste Water Treatment

The Kynch theorem was extended to non-linear system of conservation laws of polydisperse suspensions of spherical particles. The simulation predicts overflow of light particles and heavy particles at steady state and dynamic mode of batch and continuous sedimentation. The model eliminated the need for imposed non-theoretical parameters or functions to predict hindered settling and efluent concentrations. Particle-size distribution is also predicted at the effluent and the underfow. We examined several cases and predicted dynamic behavior of rarefaction waves and overloaded continuous settler. A new concept of dynamic flux curves is also used and introduced.

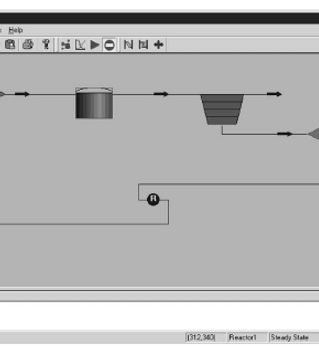

Applying Thermo

In process engineering and design, thermodynamics theory is applied to real and complex chemical-process applications. Software design simulators, such as HYSYS, PROII and Aspen Plus, serve as powerful tools that simplify process thermodynamic calculations. They eliminate the need for the engineer to solve complex differential equations, and they allow the application of variety of property packages to the modeling of unit operations. In a highly competitive setting where time and technical competency are critical, the proper and accurate use of these simulation tools can be of great value. However, an overreliance on simulation can lull the user into a disregard for the underlying engineering principles. Conversely, a lack of solid engineering knowledge can induce the user to reject some simulation results that are, in fact, fully valid. In either case, among the most serious consequences can be flaws in the relevant material and energy balances, which are fundamental to a valid design. Consequent errors in the front-end design can lead to major engineering-revision costs, if they are detected in the detailed engineering phase; and if they are not detected there, then the consequences for the project and plant can of…